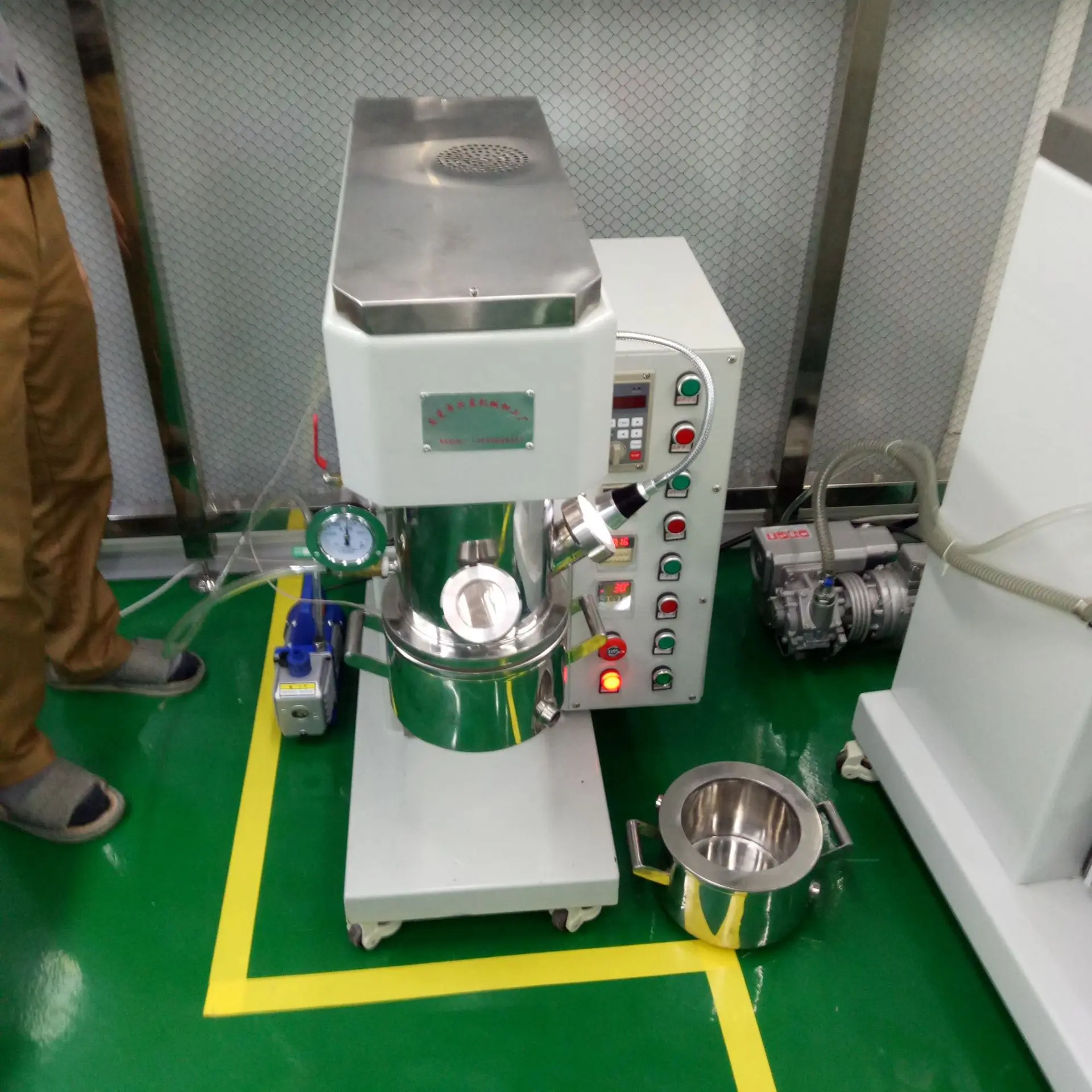

Dongguan City, Guangdong Province Mechanical planetary mixer Silica gel mixer SMT mixer tin Item NO.: 1941939

Copy and share this link on social network or send it to your friends

Copy- Dongguan City, Guangdong Province Mechanical planetary mixer Silica gel mixer SMT mixer tin

| Product Name | Dongguan City, Guangdong Province Mechanical planetary mixer Silica gel mixer SMT mixer tin |

| Item NO. | 1941939 |

| Weight | 10 kg = 22.0462 lb = 352.7396 oz |

| Category | Explosion-proof electrical apparatus |

| Creation Time | 2022-04-17 |

Please contact customer service

Price is not the real price

Bargaining is necessary

Equipment features:

1. Low operation noise and excellent use stability, widely accepted by users at home and abroad;

2. Exquisite appearance: high quality paint / stainless steel surface is used for mirror polishing / fine treatment of welds;

3. Competitive price and performance price ratio; the same price, the best / most reasonable configuration;

4. Optimize the overall structure layout;

5. Use frequency converter to realize frequency control: LG (commonly used), Delta, Mitsubishi, Fuji and other imported brands, and domestic brands (commonly used);

6. Scientific and reasonable selection of O-ring: see "performance comparison table" of after-sales service for various rubber properties;

7. Excellent vacuum holding performance: gauge pressure - 0.098mpa → - 0.090mpa for more than 24 hours;

8. The unique design and manufacture of grinding basket and grinding rod ensure grinding effect and prolong service life:

(1) . the grinding basket is made of fine, solid and durable;

(2) The internal framework of the grinding rod is 304 stainless steel and the external one is wear-resistant sintered zirconia ceramic;

(3) . unique baffle design to prevent grinding beads from popping out;

9. Scientific and reasonable mixing paddle design, diversified selection and combination design:

(1) . spiral twist type / straight frame type;

(2) . multi blade / anchor / butterfly;

(3) . other irregular agitators;

(4) . low clearance:

(4) - A. mixing paddle - mixing paddle (6mm + 2.5mm, normally 3-5mm)

(4) - B. agitator - inner barrel wall (4mm + 1.5mm)

(4) -c, impeller bottom (3mm +2mm);

(5) According to the type of machine and the environmental conditions, the reasonable and scientific combination design is carried out.

10. Various mixing / shearing (dispersion) / homogenization (emulsification) / grinding options:

(1) . planetary dispersion mixer / dispersion mixer;

(2) . power mixer: single part single mixing, single part double mixing, double part single mixing, double part double mixing;

(3) 2-axis planetary stirring / 3-axis planetary stirring;

(4) . multifunctional mixer (high-speed dispersion mixer);

(5) . others: high speed disperser, screw mixer, large-scale stirring reactor and other equipment.

11. Safe operation guarantee setting: by using frequency converter, limit travel switch and proximity switch, through special circuit design, ensure that:

(1) . the upper can body (or lifting cylinder) will automatically stop when it is raised to its position;

(2) . limit the operation of the machine during the rise of the upper can body;

(3) . when the machine is running, the upper can body (kettle cover) cannot be raised or the mixing bucket cannot be lowered;

(4) . when the atmospheric pressure is not restored, the upper can body (kettle cover) cannot rise or the mixing bucket cannot fall;

(5) . the guide rod is provided with an anti cylinder automatic lowering bolt;

12. The unique and reasonable wall scraping design can minimize the damage to the inner tank of the mixing drum;

13. Oil leakage prevention measures:

(1) . reasonable use of oil resistant rubber: some O-rings, framework oil seal;

(2) . unique mechanical seal seat design to better prevent oil leakage;

(3) . unique beam baffle structure;

(4) . use oil slinger and reasonable guard structure of planetary case at the end;

14. Loading process:

1. High precision electronic sensor is used to give signals, and Mier type precision valve and famous brand control appliance are used for charging valve

You May Also Like

Recently Viewed

Company Info

User Center

Payment & Shipping

Contact Us

Hello, welcome to Yueqing Chaohuang Electrical Appliances Co., Ltd. Customer service did not reply to you immediately. Please leave your Email address WhatsApp number wechat number skype facebook number or other chat number. Customer service will contact you as soon as see it.

whatsapp +8615058371692 Email cnzhaohang@163.com WEchat +8615058371692 skype +86 15058371692

TEL +8615058371692

Web site

https://cnzhaonhang1989.en.alibaba.com

No related record found